FOCUS ON QUALITY

Our specialty is offering high-quality, versatile fabrics, sourced from local textile mills. At the same time, we also offer fabric customization services and can produce fabrics according to your design requirements. The factories we cooperate with strictly adhere to quality standards and tests.

We always firmly believe that quality is the foundation of everything whether in fabric and garment.

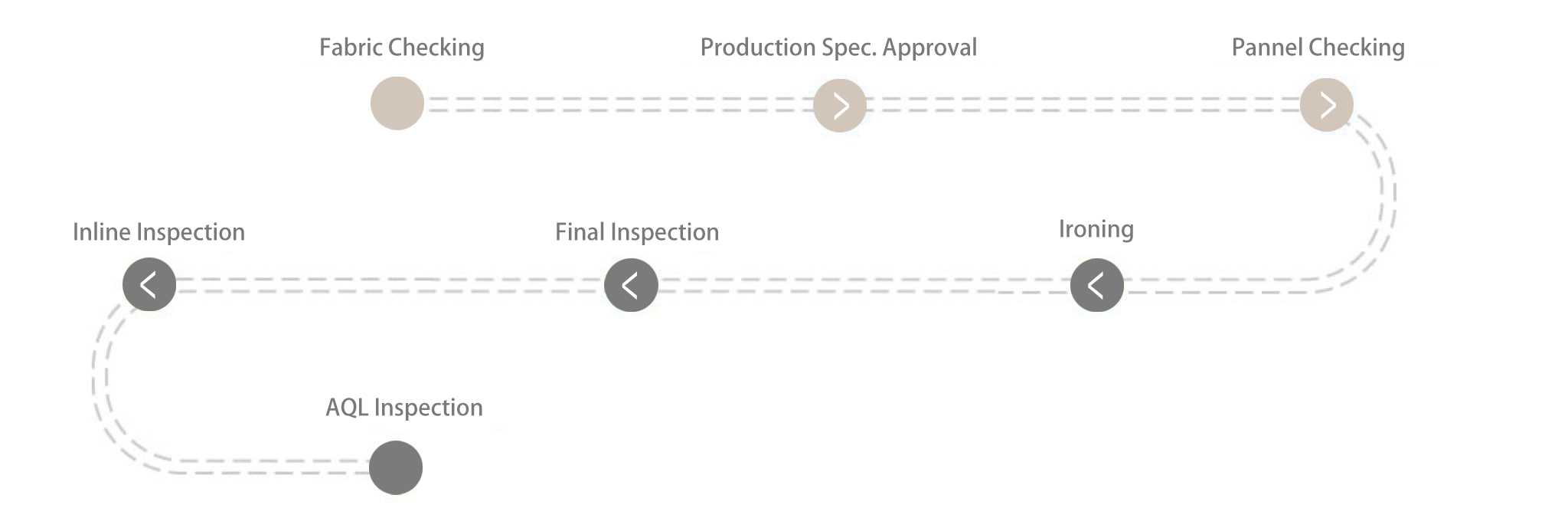

Here is the quality journey which each of our order follows 1. Fabric Quality Control

|

Quality process route we follow for bulk production

Weight and Composition: Make sure fabric meets the required weight (e.g. 120gsm) and correct fiber content (e.g. 100% cotton).

Once this fabric passes the required in-house and third party testing its passed for production.

Weight and Composition: Make sure fabric meets the required weight (e.g. 120gsm) and correct fiber content (e.g. 100% cotton).

Once this fabric passes the required in-house and third party testing its passed for production.